The following is an interview with Klaus Reichardt, CEO and Founder of Waterless Co. Inc., for a university campus publication.

Question: What are some initial and long-term benefits for colleges that install waterless urinals?

Installing waterless urinal systems can offer several benefits to building managers.

Firstly, the installation cost is significantly lower as waterless urinals do not require flush handles, sensory systems, and incoming waterlines necessary for conventional urinals.

Secondly, waterless urinal systems rarely require plumbing repairs. For instance, one popular restaurant/bar manager shared that after a busy Saturday night, it was common for at least one of the restaurant's conventional urinals to be broken or clogged with debris. However, with waterless urinals, this rarely happens.

Thirdly, waterless urinals can help keep water bills in check, which is a significant cost-saving factor. Since 1991, the average water bill in the U.S. has risen about 50 percent, higher in some areas, making it a growing cost concern for building managers.

What Costs are Associated with Installing Waterless Urinals?

The most significant costs involve the trap/cylinders placed at the base of the urinal. Some no-water urinals require more frequent changing of these trap/cylinders than others, which can undermine the expected cost savings. Interestingly, the brands that require frequent trap/cylinder changes are also the most expensive, with some costing as much as $50 each. However, with our urinals, the trap/cylinder costs only about $10 per unit.

How Much Water Do They Save?

A conventional urinal uses 20,000 to 45,000 gallons of water per year. A waterless urinal uses no water at all. Further, some manufacturers of these urinals recommend flushing a gallon of water down the urinal each month. We do not. That rarely is necessary with our urinals, further helping to keep water consumption to a minimum.

How does waterless technology work?

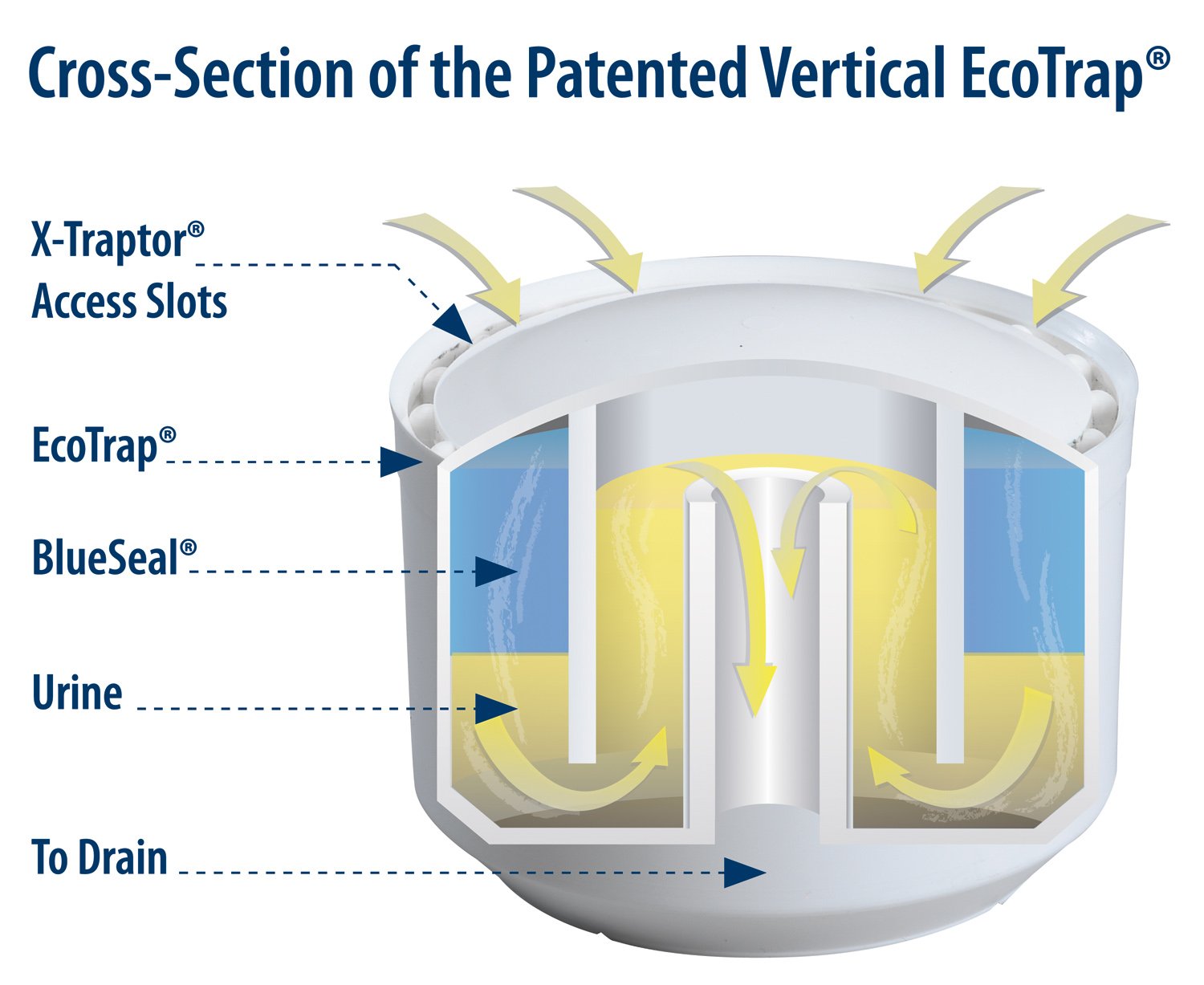

The way waterless urinal systems work is quite simple. Instead of using water to flush away urine, gravity drains the urine into the trap/cylinder we just mentioned.

We use the Eco-Trap cylinder. It is filled with a thin layer of liquid sealant called BlueSeal, which must be refilled as necessary and, in most cases, is a quick and easy procedure.

As the urine passes through the trap/cylinder and sealant, the urine overflows into a conventional drainpipe, much like a traditional urinal works.

How long has your company offered these fixtures, and what has customer feedback been?

We have been in business since 1991. That tells you a lot about our products and our company. The urinals work and work well. Further quality customer service is always our goal. We keep our customers happy with our products and quality service.

What’s the Connection Between No-Water Urinals and LEED?

The Leadership in Energy and Environmental Design (LEED) program has gotten much more focused on reducing water consumption than ever before. Facilities that install waterless urinals often find the water saving is so significant that this is all they need to earn water-related points and pass this criterion of the LEED program.

Can you comment on any other trends in water waste reduction you have noticed on college campuses?

It is hard to believe today, but at one time, toilets installed in schools and colleges in the U.S. used as much as eight gallons of water per flush (gpf). Today, they use 1.6 gallons of water per flush (gpf).

Similarly, pre-1992, conventional urinals used three to four gpf. Now, they use about one, but we consider that one too many.

The trend I see in the future is the increasing need to reduce water consumption around the world and to use water more efficiently. With each passing year, we see this as a growing concern.

Fortunately, waterless urinals are helping stem water consumption today, not only in North America but around the world.

Klaus Reichardt, CEO & Founder at Waterless Co Inc. He is widely known as a thought leader and influencer when it comes to water related issues. Waterless company helps facilities use water more efficiently, reduce water consumption, and lower operating costs.